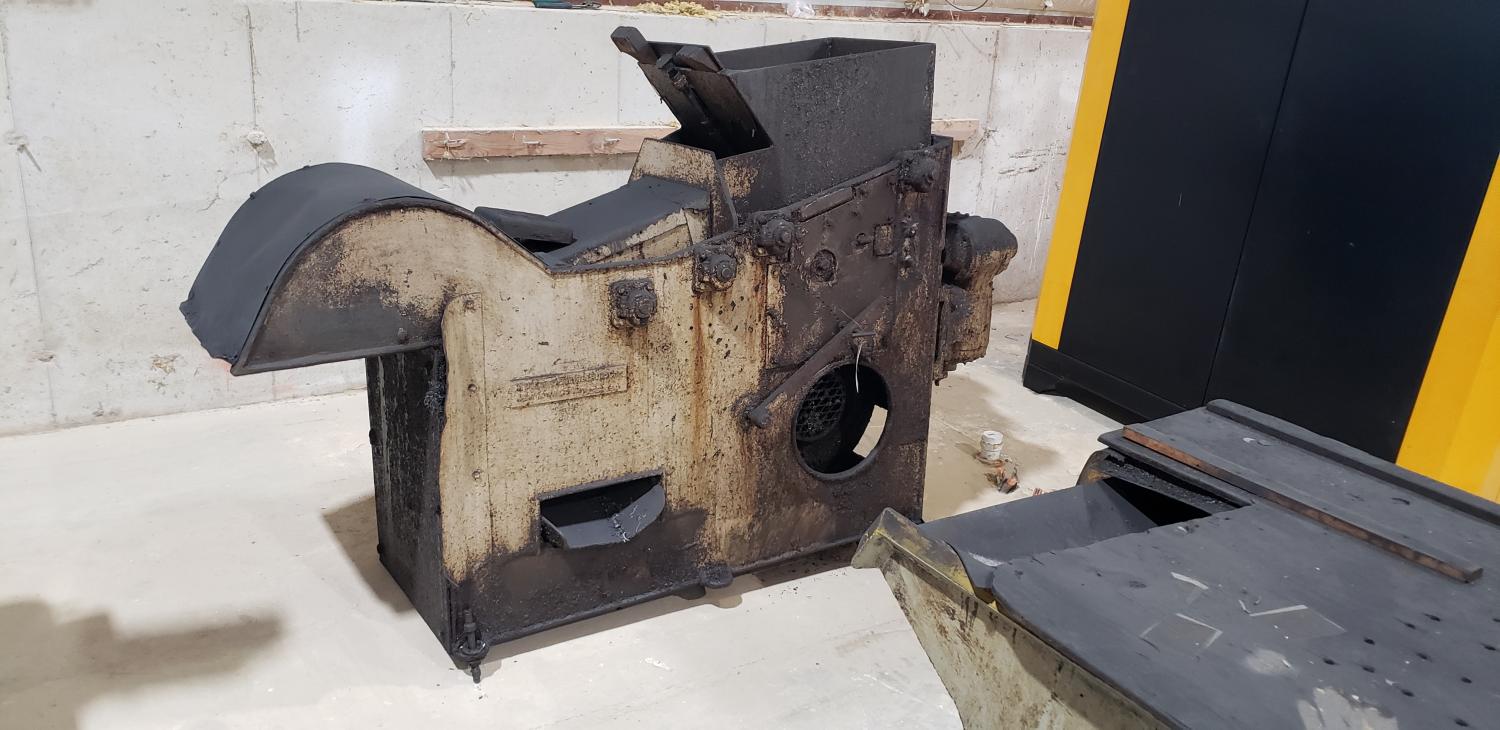

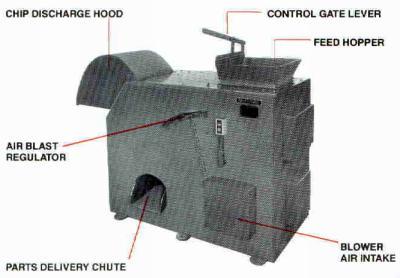

McKenzie Model L Chip Separator

Size range (diameters): 1/8″ to 2″ (3 to 50mm)

Size range (lengths): 1/4″ to 6″ (6 to 152mm)

Maximum Operating rate: 1 cu. ft./min. (approx 5000 parts/min)

Average operating rate: 34cu. ft./hr., using varying parts and sizes

OPERATION:

1. Adjust air blast regulator lever to regulate air flow for size and weight of the parts.

2. Set control gate in feed hopper to permit uniform flow. (Normal setting: 1-1/2 times diameter of parts to be separated.)

3. With machine running, and after cutting oil has been removed, empty production to be separated into automatic feed hopper.

4. Production will feed into vibrator where, by means of constant agitation, material is spread evenly prior to entering controlled air stream. That’s all. The chips are automatically discharged below the chip discharge hood, while the clean parts drop from the parts delivery chute.

SPECIFICATIONS

Blower Motor 5 H.P., 3600 RPM, continuous rated, ball bearing totally enclosed

Feeder-vibrator motor 3/4 H.P., 1200 RPM, continuous rated, ball bearing totally enclosed

Current Three phase 230/460 volts, 60 Hz (currently set for 460v)

Motor control Magnetic starter, with current overload protection panel and pushbutton station

Air blower control Over 48 air regulator settings, for accurate control over complete blower range

Bearings: Connecting Rod Self-aligning roller Drive Shaft Ball-bearing pillow blocks Vibrator Pan Self-aligned grooved and graphited bronze

Lubrication Only six Alemite grease fittings for complete lubrication

Dimensions 6’4″L x 4’2″H x 3’W (193 x 127 x 91 cm)

Shipping weight (domestic) 1520 lbs. (690kg)

https://web.archive.org/web/20220929235856/https://mckenzieengineering.com/model-l.html

Additional information

| Weight | 1200 lbs |

|---|---|

| Dimensions | 81 × 32 × 56 in |